Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

Table of ContentsThe Motorcycle Parts New Zealand Specialists PDFsSome Known Incorrect Statements About Motorcycle Parts New Zealand Specialists 8 Easy Facts About Motorcycle Parts New Zealand Specialists ShownThe 45-Second Trick For Motorcycle Parts New Zealand SpecialistsExamine This Report on Motorcycle Parts New Zealand SpecialistsIndicators on Motorcycle Parts New Zealand Specialists You Need To KnowSome Known Questions About Motorcycle Parts New Zealand Specialists.See This Report about Motorcycle Parts New Zealand Specialists

So, get to out to among our experts today.CNC machining technology is promptly coming to be the centerpiece of various manufacturing procedures around the globe as a straight result of its numerous advantages over various other methods. Additionally, the sectors that make motorcycles have hopped on board with this fad. The most innovative firms are currently creating their engine parts and wheels using machining strategies originally developed for motorbike components.

You might be wondering why we utilize. Now that we have your attention let us describe the rationale behind this modern-day growth in the motorcycle production market.

What Does Motorcycle Parts New Zealand Specialists Do?

In enhancement, you have full control over the appearance of the elements, even down to the min information. Occasionally, motorcyclists may make a decision to spruce up their ride by installing aftermarket parts or modifying the bike's remodeling.

Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know

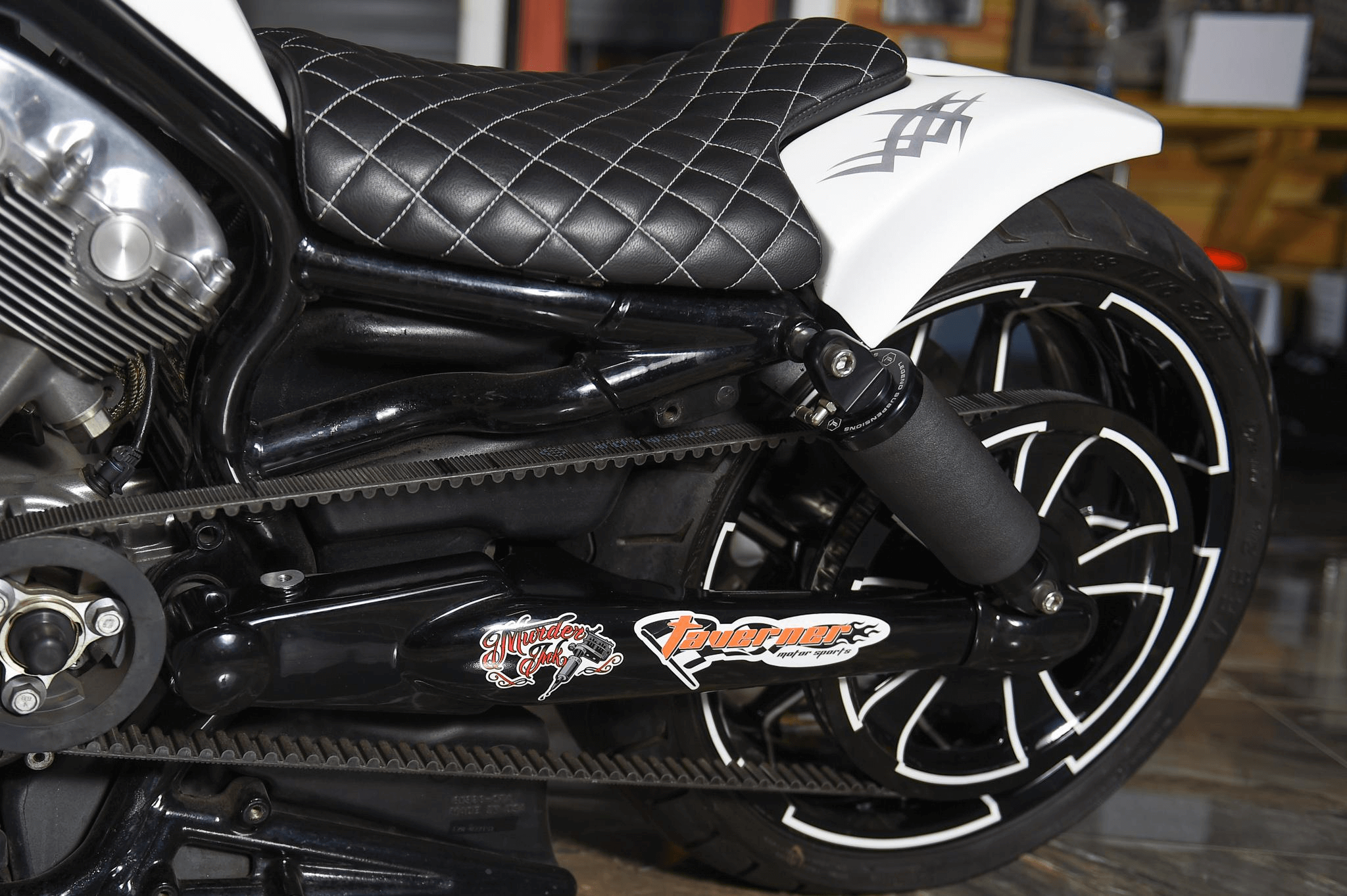

CNC machining might be used to make nearly all of a bike's metal and plastic parts. To proceed, we'll talk about several machined parts for motorbikes. In comparison to those on automobiles, wheels on motorcycles have a tendency to be extra apparent. As a result, the bike's looks may be improved with the suitable personalization of these wheels.

Milling procedures are used to acquire the wanted degree of wheel customization. An additional facet of the motorbike that might be individualized is the tires.

All about Motorcycle Parts New Zealand Specialists

When it involves a vehicle (or a motorcycle), the most important component is the engine. Numerous people mention it as the "heart" of the automobile. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and require styles with a high degree of accuracy.

Usage just top quality items, nevertheless, because these lights are critical for the safety of motorcyclists and other motorists or individuals on the road, particularly at night. Motorcycle fronts lights have 3 main parts: the light bulb, or light resource, the lens, and the real estate.

Milling procedures with a flawless surface would certainly lead to the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not composed of breakable products; instead, it is created out of challenging polymers that can be machined right into even more complex patterns.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

Motorbike producers typically cast these parts, however only for the manufacturing of bespoke components. Machining on 5 axes in today's globe is the methods by which any style shape might be recognized.

Choose Runsom for your customized motorcycle components! We have the capability to produce challenging and trendy elements making your motorbike matchless.

Right here are a couple of instances of steels frequently made use of in motorcycle element machining. Light weight aluminum is the primary product used by firms specializing in producing custom-made motorcycle components to additional resources produce many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes one more metal that is really light in weight and has great machining qualities due to its high mechanical toughness. This material may be developed into practically any kind of shape and preserves its measurements well. Also mission-critical parts that need a high level of accuracy might benefit from their use.

Indicators on Motorcycle Parts New Zealand Specialists You Need To Know

Another steel that sees hefty usage in the production of CNC-customized parts is magnesium. It is amongst the lightest steels that are now available and has excellent machinability features and strength commensurate with its reduced weight. One of the drawbacks of magnesium is that its dirt might conveniently catch fire.

Their most usual usage in generating different bike components is fasteners, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them suitable for this usage.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

It appears that CNC turning and crushing are the fundamental procedures. However, alternative methods exist, such as exploration. Allow's explore much of these machining strategies in deepness. The CNC turning technique is considered a subtractive manufacturing approach. On top of that, it calls for maintaining bars of product, most typically plastic or steel, ready and afterwards twisting a cutting device to remove areas of the product as the product is turned.

These methods are similarly important and produce parts with high precision and constant top quality. They are respectively: grinding, laser cutting, and boring. The term "surface coating" describes post-processes after the initial machining stage. Motorcycle Parts New Zealand Specialists. The processes help boost the overall top quality of the machined motorcycle parts. Below are the short about his introduction, pros and disadvantages of five surface treatment approaches.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists